Multiphase Modelling of Coffee Bean Roasting

- Researcher: Nabil Fadai

- Academic Supervisors: Colin Please and Robert Van Gorder

- Industrial Supervisors: Robert Farr and Fabien Guilmineau

Background

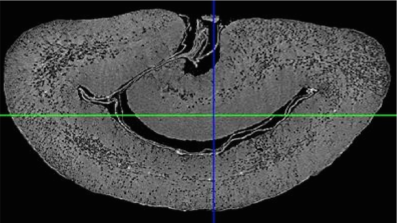

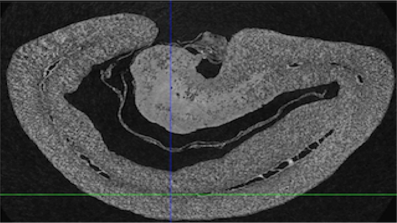

The coffee industry is worth more than $100 billion worldwide per year, making coffee one the most valuable commodities in the world. One rather fundamental step in coffee production is the roasting of coffee beans. Most of the publications concerning the roasting of coffee beans present experimental data and use regression analysis and simple empirical models to interpret the results. In this project, we aim to provide insight to the industrial coffee roasting process from a theoretical perspective. Specifically, we wish to describe processes such as drying and evaporation, simplified chemical reaction pathways, and expansion/deformation of a coffee bean as it is roasted from its unroasted state (left panel below) to its roasted state (right panel).

Outcomes

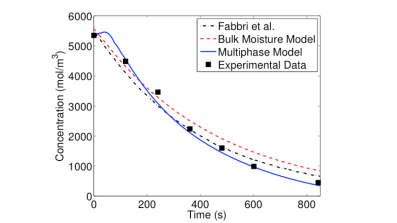

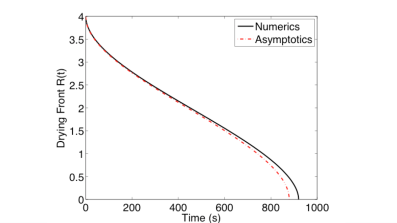

In [1], we derived a multiphase heat and mass transfer model to describe the temperature and moisture content of a roasting coffee bean. By dividing the coffee bean into solid, liquid, and gas phases, we are able to capture local phenomena into the model, without having to simplify the coffee bean structure to a “bulk” material, while also agreeing with experimental data (left figure below). In [2], we examine this multiphase model in more detail via asymptotic analysis. Specifically, numerical solutions of the multiphase model indicate that a “drying front” divides the coffee bean into a moist and dry region, despite the drying front never being prescribed by the model. Using asymptotic analysis, we are able to determine not only the approximate solutions of temperature, water content, and vapour pressure within the roasting coffee bean, but also an approximate form of the observed drying front that agrees well with the numerical solutions (right figure). Finally, in [3], we extend the multiphase model to incorporate general chemical reaction groups observed in the roasting process. Additionally, we consider more general geometries and evaporation rates to allow for further agreement between the extended model and new experimental data. For the remainder of this project, we included elements of solid mechanics in these multiphase models. Specifically, we examined how the cellulose structure of the coffee bean changes from a rigid, elastic structure to a viscoelastic material upon exceeding a critical glass transition temperature. This transition temperature depends on the moisture content of the bean and is predicted to first occur in the interior of the bean rather than at the surface. By modelling the cellulose structure as a poroviscoelastic material, we observe that, due to the dramatic change of viscosities at the glass transition temperature, a large build-up of material stress occurs between the onset of the glass transition and when the glass transition occurs at the surface of the bean. This build-up of material stress can be linked to macro-scale deformations and fracturing that occur in the roasting process.

Publications

[1] N. T. Fadai, J. Melrose, C. P. Please, A. Schulman, R. A. Van Gorder, A Heat and Mass Transfer Study of Coffee Bean Roasting. International Journal of Heat and Mass Transfer 104 (2017), pp. 787-799.

[2] N. T. Fadai, C. P. Please, R. A. Van Gorder, Asymptotic Analysis of a Multiphase Drying Model Motivated by Coffee Bean Roasting. SIAM Journal on Applied Mathematics 78 (2018), pp. 418-436.

[3] N. T. Fadai, Z. Akram, J. Melrose, F. Guilmineau, C. P. Please, R. A. Van Gorder, The Influence of Distributed Chemical Reaction Groups in a Multiphase Coffee Bean Roasting Model. Accepted to IMA Journal of Applied Mathematics 8/5/2018.