The formation of liquid drop patterns on solid surfaces is a fundamental process for both industry and nature. Now, a team of scientists including Oxford Mathematician Andreas Münch and colleagues from the Weierstrass Institute in Berlin, and the University of Saarbrücken can explain exactly how it happens.

Controlling and manipulating liquid drop patterns on solid surfaces has a diverse range of applications including in the coating industry as well as in developing tools for use in cell biology. These are also essential for the famous ‘lotus leaf’ effect where the leaf self-cleans. Now, as they explain in an article in Proceedings of the National Academy of Sciences of the United States of America (PNAS), the team has identified that the formation of droplets during a dewetting (retraction) of a thin liquid film from a hydrophobically (water repellent) coated substrate is essentially controlled by the friction at the interface of the liquid and the solid surface.

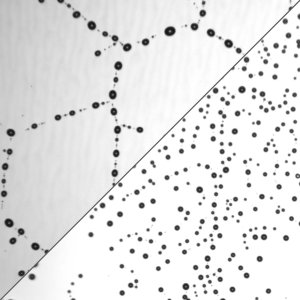

The mathematical models and the highly adaptive numerical schemes developed by the team predict very distinct droplet patterns that include both the large-scale polygonal structure of ensembles of micro-scale droplets to the small-scale cascades of even smaller satellite droplets (see picture). These results were achieved simply by varying the condition at the liquid-solid boundary, a so-called Navier-slip-type condition.

In the experiments, the surfaces were treated with different surface coatings that made them particularly slippery, thereby reducing the interfacial friction. As a result, the theoretical predictions, from the large-scale to the small-scale patterns were confirmed.

It is now possible for a trained observer to "see" the friction exerted by the surface coating and relate the multi-scale pattern to the corresponding interface condition and the presence of slip. This has great potential, not only for spotting similar conditions in nature, but as a facile, non-invasive tool for designing patterns in many micro-fluidic applications without the need for pre-patterning or lithographic treatment of the surface. These would include bespoke synthesis of monodisperse (uniform) materials or biosensor applications.