When compressed along its longest dimension, a thin structure such as a playing card collapses into a bent shape that accommodates the imposed compression without a significant change of length. This phenomenon of buckling under compression is ubiquitous in structural mechanics: bridges, marine vessels, and aerospace structures all risk failure due to buckling. Buckling is also widespread in nature: microtubules buckle within the cytoplasm and plant stems bend under their own weight. The prevalence of buckling across length scales is explained by the scale-free character of the theory of elasticity, which provides the mathematical description of buckling, and the relative slenderness of the structures. What matters is not the absolute length scale, but the aspect ratio.

Historically, buckling has been regarded as a route to failure and structural collapse, and its study has been driven by the need to prevent its catastrophic consequences. However, in recent years, a novel perspective has emerged. In this modern paradigm, the control of buckling, and mechanical instabilities more broadly, is desirable for its potential to actuate new functionalities in engineered structures, especially in the emerging field of soft robotics. This paradigm shift has also led to the identification of buckling as a means to render functionality in natural systems: for example, uniflagellated bacteria use buckling for steering, and the shape-switching of a spider silk thread is induced by buckling.

A study published in PNAS, a joint work by theorists in Oxford Mathematics and engineers at the Nanyang Technological University of Singapore and the University of Birmingham, introduces a new means for actuating a sheet by tension-induced buckling. Using a combination of experiments, mathematical modelling and numerical simulations, their work establishes a theory that describes the buckling and subsequent folding of a uniaxially stretched sheet.

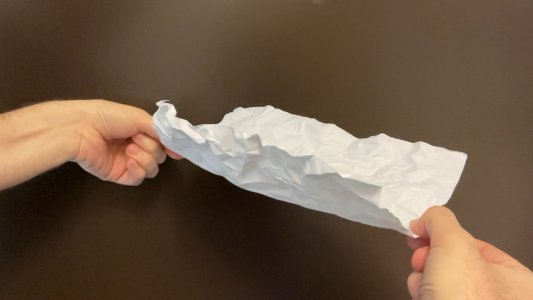

An informal demonstration of the results can be done using a crumpled paper sheet:

1. Crumple a rectangular piece paper;

2. Open it out again;

3. Clamp the centre of the short edge between thumb and finger;

4. Pull along the long axis.

Initially, the sheet stretches and remains flat. But at a critical extension, it folds transversely. The theory developed provides a scaling law for the fold angle in terms of the sheet's dimensions, mechanical properties (i.e. its resistance to deformation), and the applied strain. The work calls this phenomenon 'localised Tension-induced Giant folding', or 'localised TUG folding', to reflect its appearance when tugging an elastic sheet.

The results also provide a rational framework for previous designs of structured sheets in which transverse folding in uniaxial tension had been used, such as in soft grippers. Examples of such structures include particular patterns of cuts, grooves and ribs. Potential applications span across length-scales, from clamped graphene sheets, to embryonic invagination and the folding of senescent leaves. Owing to the scale-free nature of the results and the generality of the model assumptions, this work speaks to a broad audience of scientists interested in solid mechanics.

Marc Suñé is a Postdoctoral Research Associate here in Oxford. You can watch a short video of Marc talking about his work below.