A Critical Analysis of Cereal Extrusion

- Researcher: Michael McPhail

- Academic Supervisors: Ian Griffiths and James Oliver

- Industrial Supervisors: Ritchie Parker

Background

A number of popular snack-food products are made using a manufacturing process known as extrusion. There is a stage during this process where some of the liquid component of the mixture changes phase to a gas. The subsequent evolution of gas within the mixture will affect its thermodynamic and rheological properties. The mechanisms at play include the transfer of: mass, momentum, and heat, as well as the change in phase of the components and the changing volume of the product. The interactions between these mechanisms will determine the final shape and texture of the product. Previous attempts to model the system during this stage of extrusion, often referred to as the flash, have only succeeded for specific, reduced cases. For example, the system becomes much more tractable if you only consider axisymmetric cases.

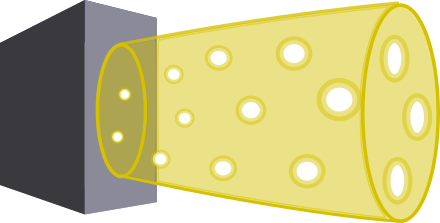

Figure 1: Schematic of a cereal extruder where, in this illustration, the cereal is flowing from left to right.

The difficulty in simulating extrusion comes from the high degree of coupling between the ongoing mechanisms. The evolution of every component in the system, from the size of the vapour bubbles that form to the temperature of the product, is dependent on the evolution of just about every other component. One way to approach this problem is to first write down a model of the fully-coupled system, and then systematically examine the impact of weakening the coupling between the components using ideas from asymptotic analysis.

A tool which can perform simulations of extrusion can be used to aid experimentation and product development by providing a relatively cheap way of testing ideas. Some of the experiments that are currently performed in labs, requiring physical equipment, can be performed theoretically. For example, when trying to design a product with a different shape, the proposed outlet shape must be built and tested in a lab. If this shape is not ideal, a new one must be built until the final product is achieved. With the aid of simulations, the effect of different outlet shapes can be tested theoretically, informing the experimentalist of a good starting design. Such a tool may also be useful in identifying potential issues, such as the formation of slugs in the extruder.

The goal of this project was to construct a model of the flash, and then use computational and analytical techniques to construct a solver capable of simulating the flash.

Outcomes

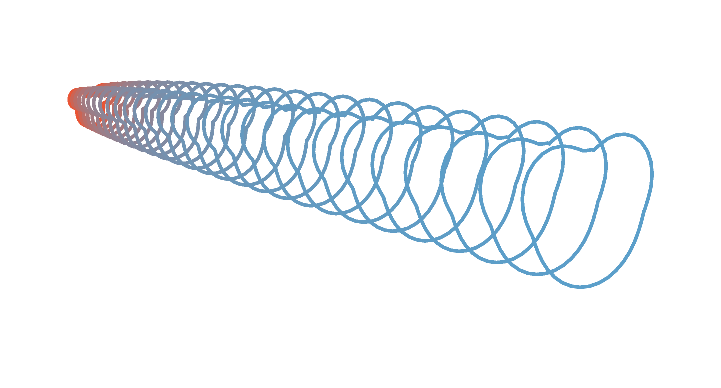

In this project we developed a number of methods for simulating cereal extrusion; the appropriate method depends on which feature of the cereal is of interest. For studying the evolution of the product’s shape, we used asymptotic analysis to simplify the governing equations so that the solution could be found by solving coupled, reduced models (see the figure below for a sample surface generated in this manner). To study the texture of the product, for which the density of the mixture is a proxy, we developed a bespoke numerical scheme. Using this numerical method, we made predictions for the variation in density throughout the final product, as well as how this variation depended on the settings of the extruder.

Figure 2: Example of shape formation during extrusion.